08-09-2020

Washnet, the “Ferrari” of carwash boxes

Washing your car. For some it’s a party, for others a necessary evil. Are you an “in front of your house” driveway enthusiast or would you rather drive into a fully automated car wash? A third option is to wash your car in one of the many do-it-yourself carwash boxes to be found all over the Netherlands. Chances are you’ll be using a Washnet carwash box powered by one of Kolmer’s energy-efficient electric motors. Michael Harskamp, owner of Washnet: ‘This electric motor is one of the many innovations I’ve implemented to make my machines better, simpler and fault-free.’

Jack-of-all-trades

Michael is a technician in heart and soul and a reliable player in this sector with 28 years of experience. ‘My father, brother and I started a company in 1992 that was mainly active for the Sanitation Department of Amsterdam. At some stage it became clear that we were also very good at building our own carwash machines. After we sold the company I started anew under the name Harskamp Techniek B.V. in 2002. Government-related activities and carwash boxes. It went well! At one point I had a staff of 12.’ Michael’s always been a jack-of-all-trades. He takes care of sales and breakdowns and is the linchpin between the accounting, technical and production departments. Everyone knows that you could buy good machines from Harskamp Techniek, but Michael wanted to take it a step further. So he started a new company entirely focused on carwash boxes: Washnet B.V.

.jpg)

SOEST – De wasstraat in Soest. FOTO LEVIN DEN BOER – KWALITEITFOTO.NL

A fault-tree installation

His mission: To develop carwash boxes that run fault-free and can be controlled remotely. Better, simpler and with as few malfunctions as possible. For years Michael and his mechanics have been providing service and they still do. However, apart from making money with it, it’s also a lot of hassle. Michael: ‘For this reason I’ve completely overhauled my machines in the past years. I want to supply carwash boxes of the highest quality. I’ve permanently solved every malfunction I’ve ever encountered. In addition, I ensure that our machines are continuously adapted to the demands of our time. Developments, both on a technical level and in terms of environmental requirements, will continue to take place and my machines respond to that.’

And if a malfunction does occur, the owner can solve it himself. Michael provides coaching by phone and, in addition, Washnet is also busy creating a video library, where the most common malfunctions can be fixed via online videos that show how it’s done. All these changes have made Michael a real trendsetter within the sector. He was also the first to opt for an IE3 motor, stainless steel housing, PC remote control and new payment systems.

Considerable price tag

He leaves a lot of specialist work, such as the complete electronics, to external parties. ‘Outsourcing control cabinet construction and software development makes for another improvement to my product.’ The result: By now, Michael sells the “Ferrari” of carwash boxes! And that comes at a price. ‘Our machine is designed to run often and for long periods. If you’ve got a prime location with a guaranteed good turnover, Washnet is the one to contact.” Michael moved the production of the carwash to Lithuania in 2017. Together with a partner, he started a new company there specialised in the building and assembly of the machines. The machines that are currently delivered to Michael are all plug-and-play.

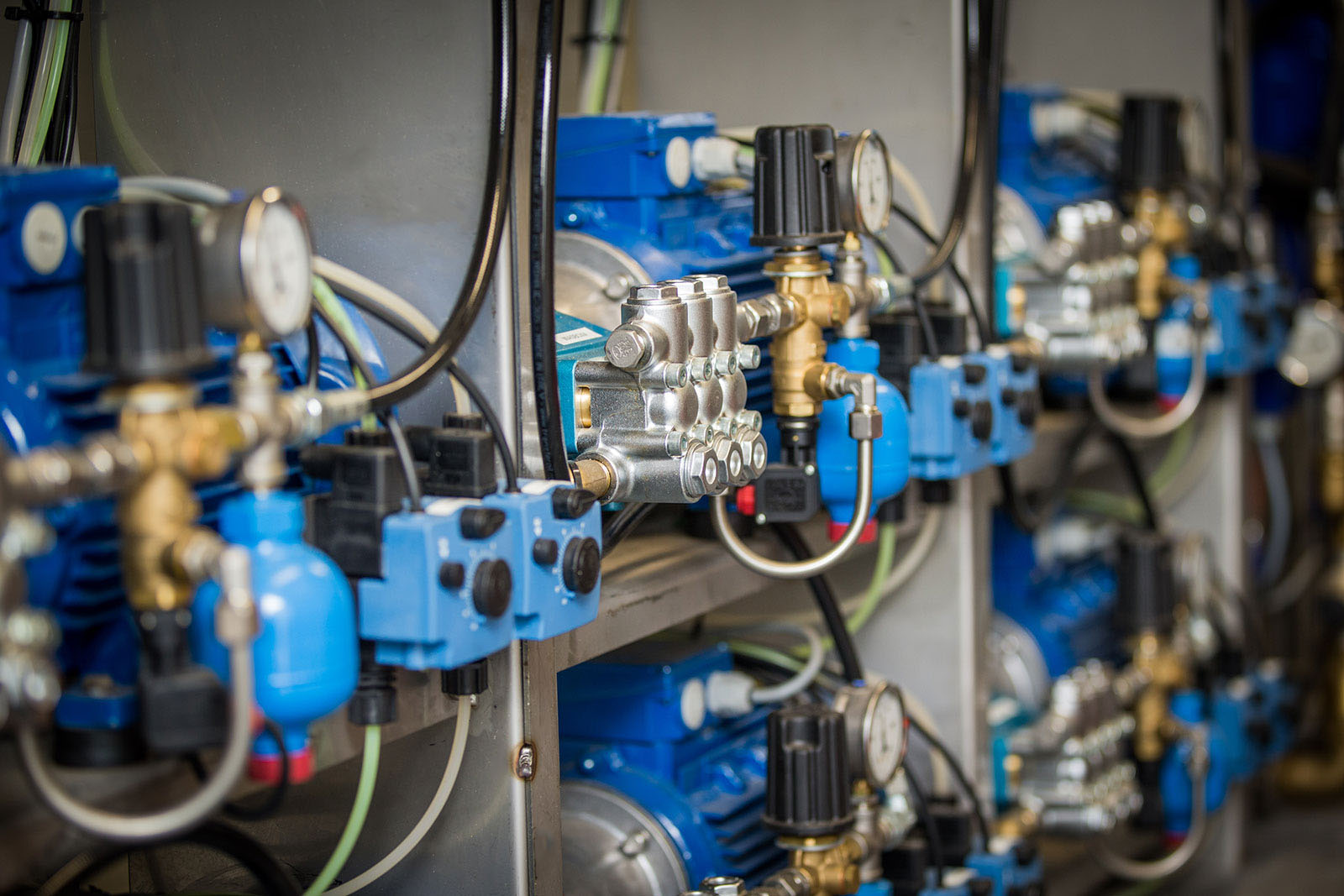

Drive of the high-pressure pump

He can’t remember exactly when he first came into contact with Kolmer, but it will probably be about twenty-five years ago. Michael: ‘Kolmer’s electric motors drive the high-pressure pumps in our carwash boxes. A basic function that allows the carwash box to operate. However, I wanted to innovate here as well and switch to an energy-efficient IE3 motor.’

Michael’s wish list:

- A quiet running motor (to extend the lifecycle of the pump).

- A more compact motor.

- Compliance with IE3 regulations.

- Efficiency in every area, both economic and ergonomic.

‘Making a 1500 rpm pump run more quietly, in combination with a lighter motor and low rpm. A higher return at lower cost, that was my wish.’ The most important condition being the construction method. IE3 motors are getting bigger and longer and will eventually no longer fit in the carwash box. ‘Together with Jan Bakker I started to philosophise and we came up with a very nice motor. We tested our prototype, took measurements and the next step was production. To save space, we used an internal shaft to reduce the size of the motor by fifteen centimetres. We were also able to remove the drive coupling between the electric motor and the pump. One less part to break. The motor is compact, energy efficient, quieter, suffers less wear and tear and meets the IE3 standard. I’m 100% happy with it!’

Service in a class of its own

Michael: ‘Kolmer’s been very proficient in sharing their thoughts and ideas regarding this motor. Not only in terms of technology, but also financially by realising a blanket order for me. There are a number of custom developed motors in stock that I can purchase whenever I want to. Kolmer is a reliable company with which I’ve never had any problems in all the years we’ve been doing business. I find their flexibility and service quite special. Suppose I have an emergency issue at one of the locations that requires the need for a new motor. So many different motors have been used in recent years: with flanges, with cooling, with different connection sizes. Kolmer will schedule a rush job for me and two hours later I can collect the right motor. All that without any additional charge. I find that service in a class of its own. Thanks to Kolmer I can really show off to my customers.’

Ambitions

Not only does he want to keep his carwash boxes simple, Michael has the same mission for his company. He doesn’t have to become mega-sized. His clientele consists of small and medium-sized enterprises and that suits him well. ‘Dealing directly with clients and owners enables me to pass on my enthusiasm for my products. I don’t like protocols and complicated procedures. Simple and fast, that’s what it’s all about. I’m there for my clients, and I want to stay on speaking terms with them at all times. If you help these companies well they will always come back to you. That’s what I’m aiming for!’

SOEST – De wasstraat in Soest. FOTO LEVIN DEN BOER – KWALITEITFOTO.NL